Supporting it all

The clarifier mechanism is available as a standard galvanized carbon steel or optional stainless steel unit, each provide many years of service.

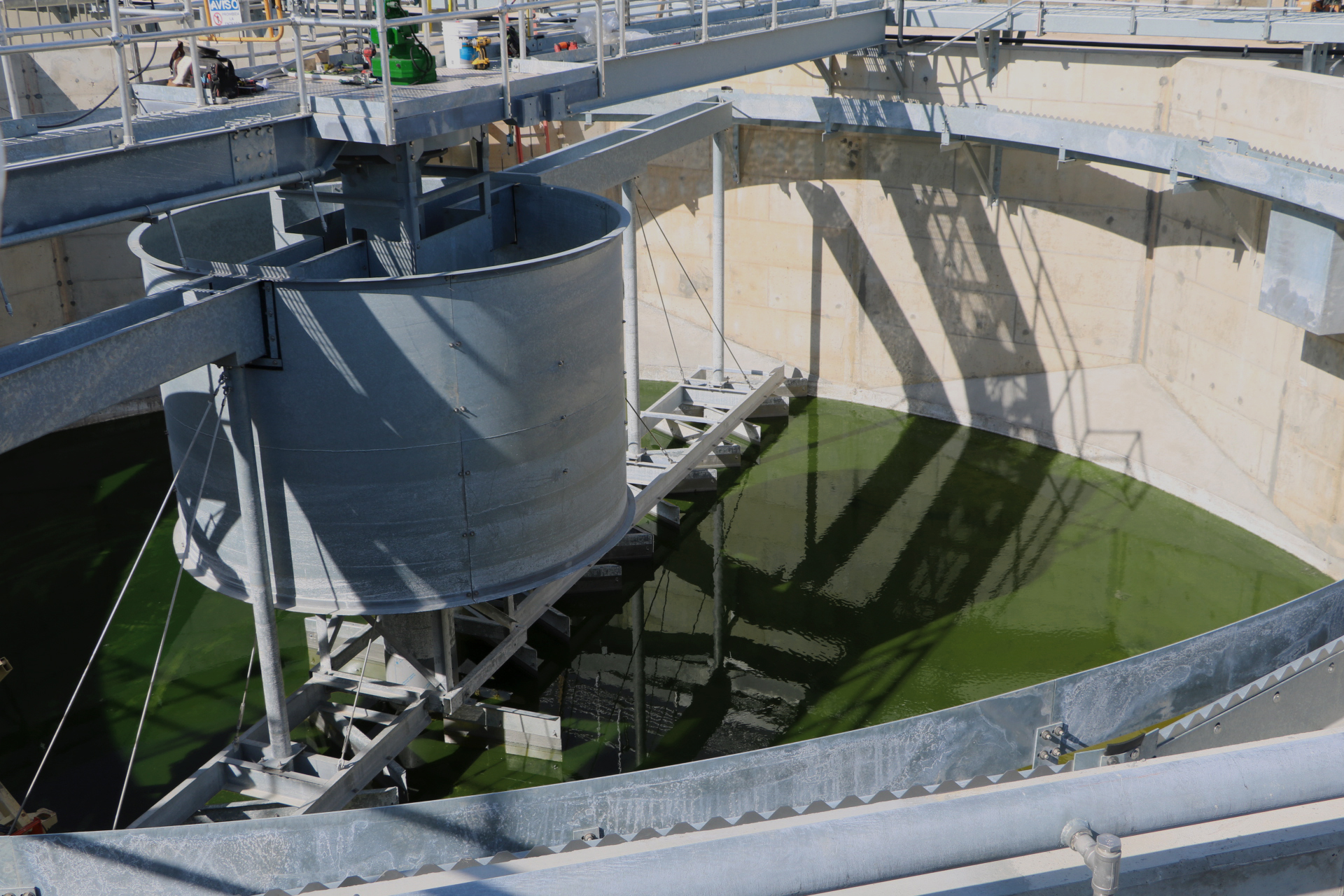

Pier Supported

Typically provided in basins for 40 feet in diameter and greater. Designed to perform under more demanding conditions.

Hydraulic Differential

The most efficient way of collecting and returning biological solids while discharging the cleanest effluent.

Bridge Supported

Typically provided in basins 40 feet and less. Designed for high arm loading factors and longevity.

GH Systems clarifier spur gear provides for bearing replacement without bridge removal or basin draining. Applications are primary sludge and tertiary settling. Plow collector mechanisms are provided in a sloped bottom basin, allowing quick and positive moving settled solids to a center sump for removal. No-clog straight tube hydraulic differential collector mechanisms provided in flat bottom basins, featuring extremely fast removal of secondary sludge. Open sludge trough allows visual inspection and sampling of removed solids. We offer full surface scum skimming with spray bars, torque monitoring and over-torque shut down, alarm contact to interface to the control panel, and/ or plant SCADA system. Standard hot dip galvanized steel mechanism and stainless steel types 304 and 316 are available.

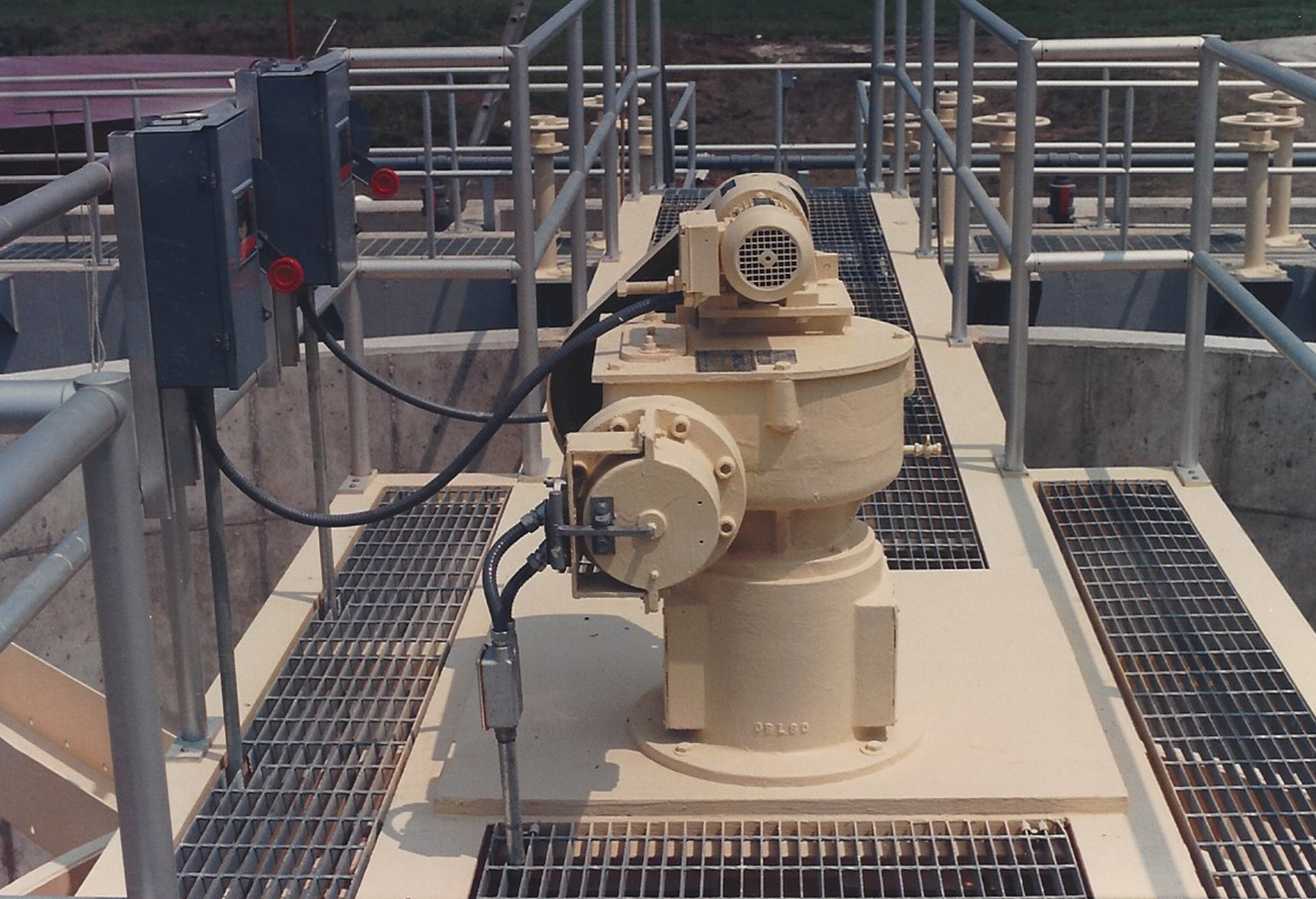

38 Special

38.4 inch PD pier supported drive gear with integral overload protection and ultra high output

The oil lubricated gear is made of high strength steel that is powder coated inside and out for decades of severe duty. It features an easy to see oil level indicator and a unique separated oil and condensate drain system for easy maintenance. All drains and fill ports are readily accessible from removable panels on the platform, and drains are furnished with hose adapters. All gear internals, including the slewing bearing, are replaceable without having to remove the bridge or platform, nor needing to dewater the basin.

Contact us

Call, Text, Email or Write

- +(512) 940-8954

- [email protected]

- PO Box 2657 Georgetown, TX 78627